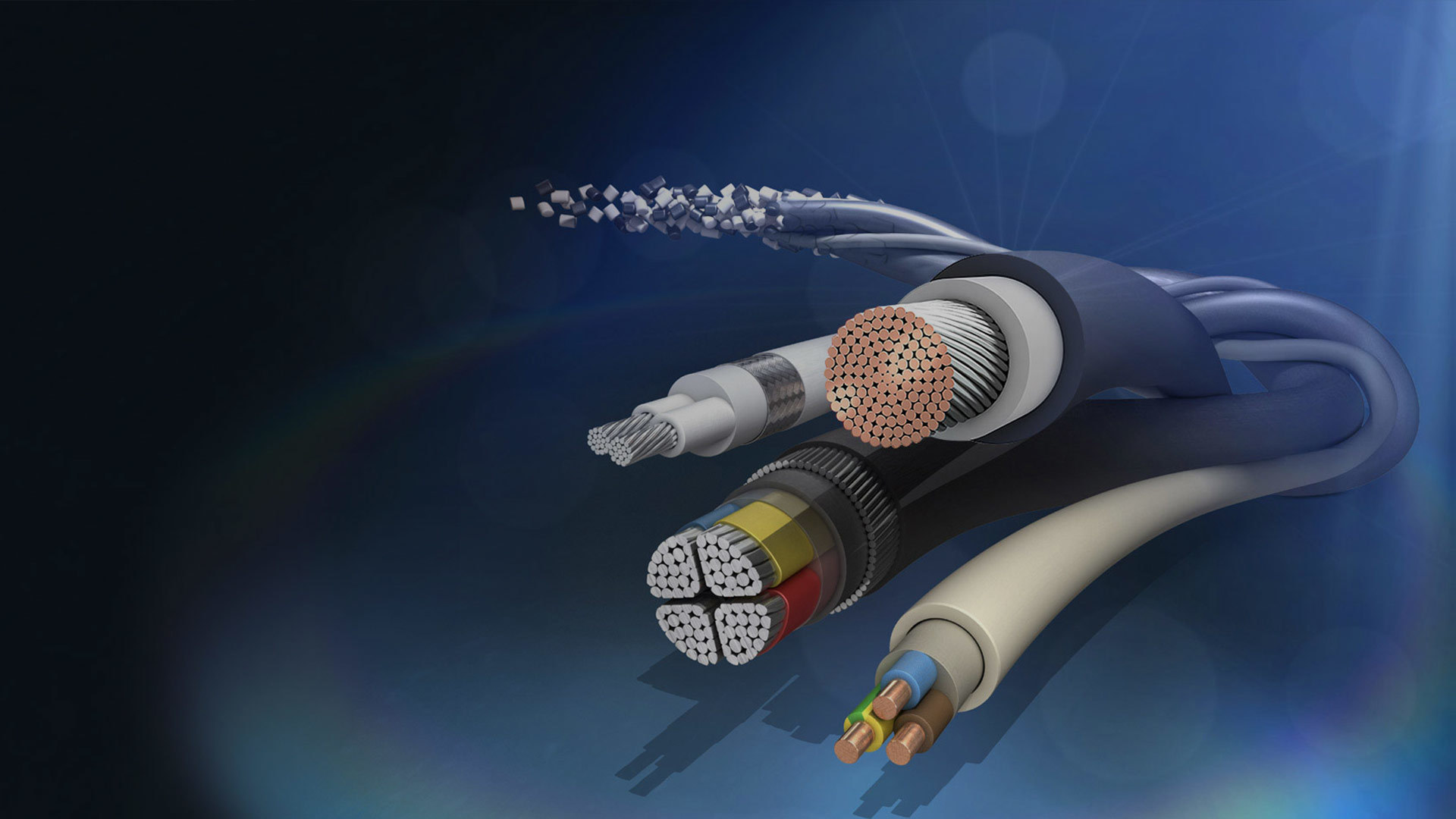

Do you know the difference between these kinds of conductor wires?

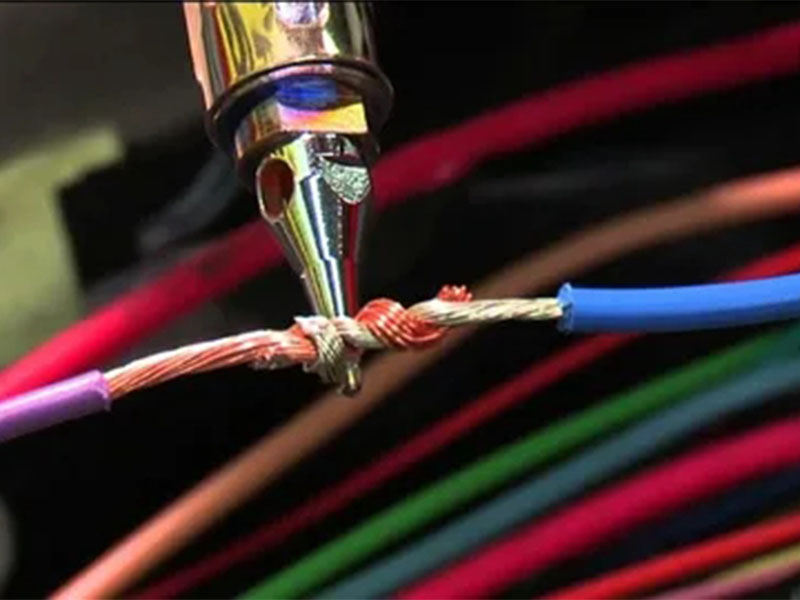

The conductor material of the wire can usually be divided into bare copper, tinned copper wire, nickel plated copper wire, etc., so what is the impact of these different conductors?

2024-01-05

How to Prevent Discoloration of Silver-plated Copper Wire

After silver plating on the surface of copper wire, it can improve the electrical conductivity, thermal conductivity and corrosion resistance of the whole wire body, which is often applied in the electronics industry, communication industry and aerospace industry. Although silver-plated copper wire is much better than pure copper wire, it is often caused by the influence of sulfide, halide, high temperature and light in the air in practical application. How can we avoid the discoloration of silver-plated copper wire? Let's take a look at it.

2024-01-05

Advantages of silver plating on the surface of metal materials

Silver is a relatively precious metal, its performance is more superior and stable than the general metal materials, so many enterprises in the actual production will do some metal silver plating treatment, in order to meet the subsequent production, application needs. There are many silver-plated products on the market, such as silver-plated copper wire.

2024-01-05

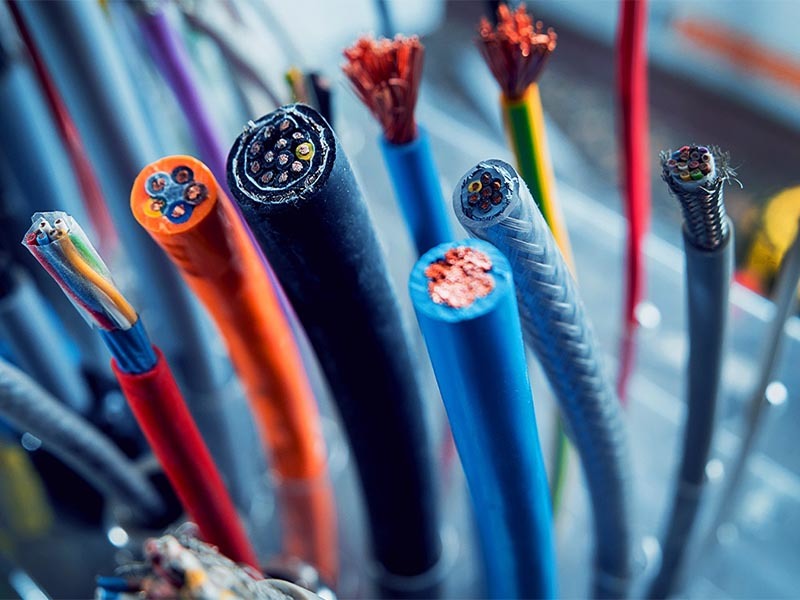

Copper wire surface coating is different, the role is also different

Copper wire is a very common type of metal in people's life and production, and it plays a different role in different industries. In the process of using copper wire in many industries, in order to improve its performance, different metals will be plated on its surface to meet the needs of practical applications. Let's take a look at the copper wire surface plated with different metals, what changes can happen.

2024-01-05

How to improve the surface of copper wire after nickel plating

The so-called nickel-plated copper wire, that is, the surface of pure copper wire by chemical method, electroplating method, etc., in its surface plated with a layer of nickel elements, in order to improve the performance of copper wire process. Compared with the previous pure copper wire, the existence of nickel-plated copper wire, whether it is corrosion resistance, wear resistance and other properties, has been significantly improved, which can bring more convenience to people's production and life.

2024-01-05

Classification of optical fiber connectors by interface type: optical fiber connectors can be divided into FC, SC, ST, LC, MT-RJ and other types according to the interface type. Among them, FC connector adopts thread locking mechanism, which is troublesome to operate, but reliable to connect and is mostly used in telecom operators or large data centers. SC connector adopts plug-in locking mechanism, which is easy to operate and is mostly used for network equipment such as routers and switches. ST connector adopts bayonet locking mechanism, which needs to rotate and fix nut during installation and is mostly used for optical fiber distribution frames. LC connector adopts small plug-in locking mechanism, small size, small insertion force, easy to install, suitable for high-density wiring; MT-RJ connector adopts dual-channel design, with high density and bandwidth, suitable for high-bandwidth applications.

2024-01-05

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Related News