How to Prevent Discoloration of Silver-plated Copper Wire

Release time:

2024-01-05

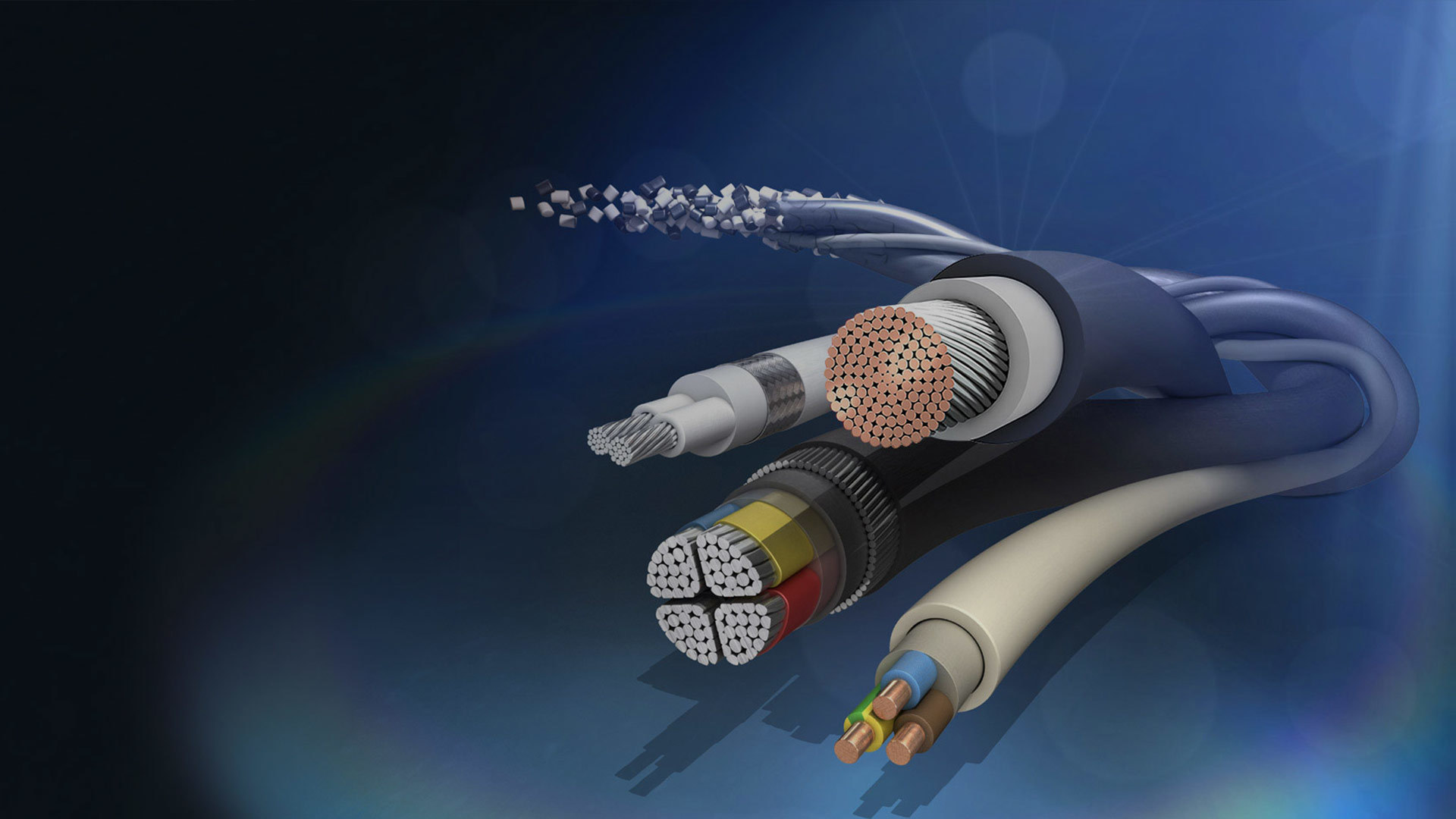

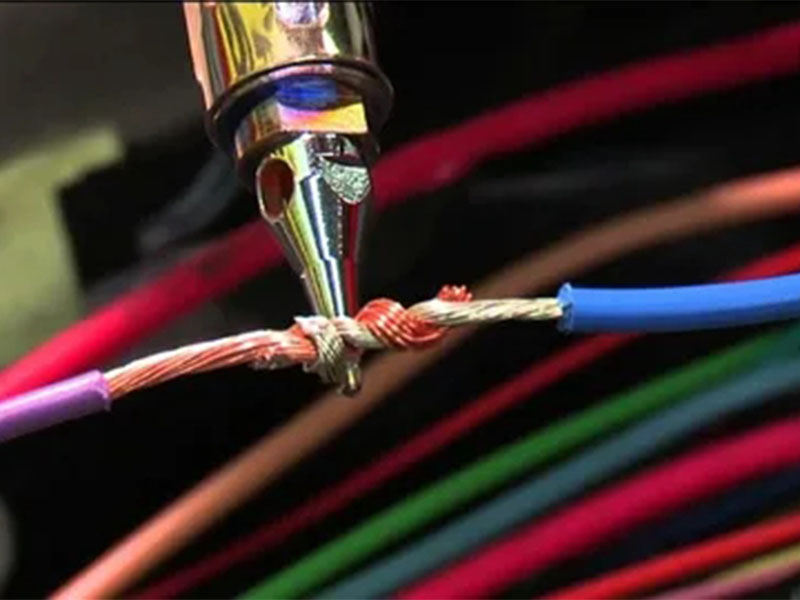

After silver plating on the surface of copper wire, it can improve the electrical conductivity, thermal conductivity and corrosion resistance of the whole wire body, which is often applied in the electronics industry, communication industry and aerospace industry. Although silver-plated copper wire is much better than pure copper wire, it is often caused by the influence of sulfide, halide, high temperature and light in the air in practical application. How can we avoid the discoloration of silver-plated copper wire? Let's take a look at it.

After silver plating on the surface of copper wire, it can improve the electrical conductivity, thermal conductivity and corrosion resistance of the whole wire body, which is often applied in the electronics industry, communication industry and aerospace industry. Although silver-plated copper wire is much better than pure copper wire, it is often caused by the influence of sulfide, halide, high temperature and light in the air in practical application. How can we avoid the discoloration of silver-plated copper wire? Let's take a look at it.

In the process of silver-plated copper wire production, pay attention to the following aspects of work, can prevent the discoloration of copper wire:

1. Increase the thickness of the entire silver plating layer and improve the tightness of the silver plating, which is of great benefit to the time of delaying the discoloration of the silver plating layer. Although there is an increase in the cost of silver plating, the possibility of occurrence of poor product productivity due to discoloration of the entire silver plating layer can be greatly reduced.

2. Improve the storage environment of silver-plated copper wire. If after the production of copper wire, conditions permit, the silver plated copper wire can be stored in the environment of 10 ℃ to 25 ℃, pay attention to keep the environment dry, do a good job of anti light and other aspects of the work, so as to avoid the possibility of discoloration of copper wire.

In the process of copper wire production, we should pay attention to the work of the operator's own protection. Such as the whole production process, can not directly touch the copper wire, do a good job in the production equipment in the mold finish protection work, to avoid scratching the silver plating part, so as to effectively maintain the gloss of the whole copper wire.

4. For the semi-finished copper wire products that have been produced, pay attention to the use of soft, environmentally friendly and halogen-free materials for packaging. In the whole wrapping process, try to isolate the silver plated copper wire from the air to avoid the occurrence of silver discoloration caused by toxic substances in the air.

After the silver plating of the copper wire, compared with the previous pure copper, its entire performance and the scope of application have been improved. Regardless of whether it is for the manufacturer or the customer, it is necessary to pay attention to its protection work in the entire use of storage, so as to reduce the impact of external factors on the performance of the entire line.

Key words:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Related News