How to improve the surface of copper wire after nickel plating

Release time:

2024-01-05

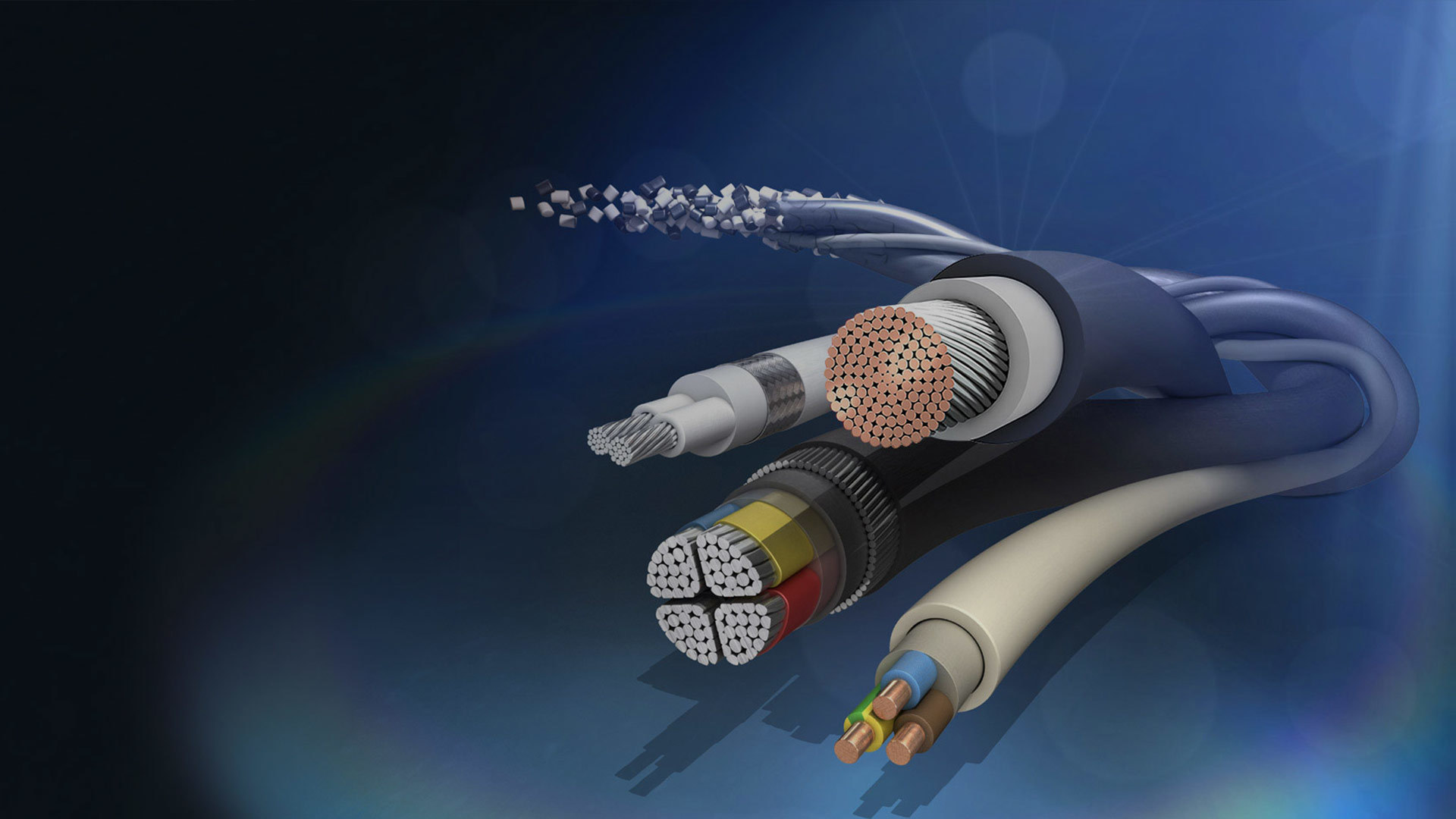

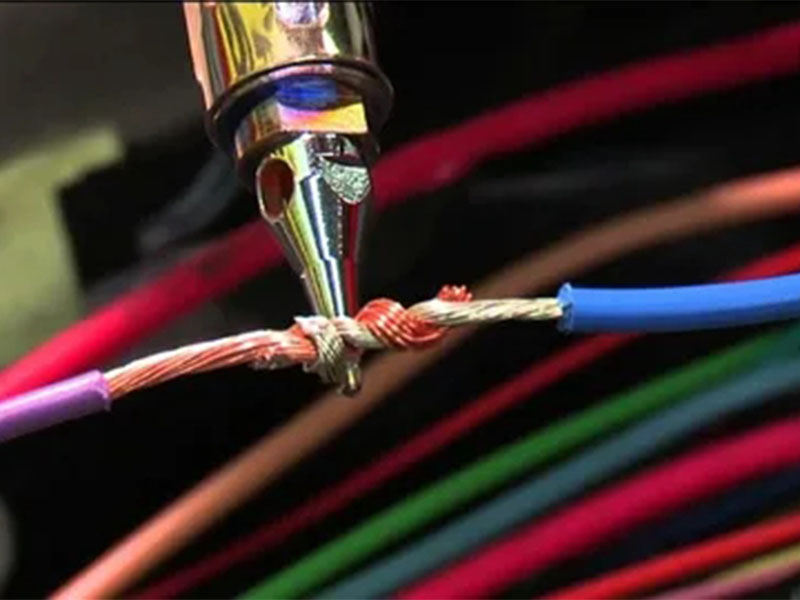

The so-called nickel-plated copper wire, that is, the surface of pure copper wire by chemical method, electroplating method, etc., in its surface plated with a layer of nickel elements, in order to improve the performance of copper wire process. Compared with the previous pure copper wire, the existence of nickel-plated copper wire, whether it is corrosion resistance, wear resistance and other properties, has been significantly improved, which can bring more convenience to people's production and life.

The so-called nickel-plated copper wire, that is, the surface of pure copper wire by chemical method, electroplating method, etc., in its surface plated with a layer of nickel elements, in order to improve the performance of copper wire process. Compared with the previous pure copper wire, the existence of nickel-plated copper wire, whether it is corrosion resistance, wear resistance and other properties, has been significantly improved, which can bring more convenience to people's production and life.

What is the promotion of copper wire after nickel plating

The parts and articles made of nickel-plated copper wire have better wear resistance, weldability and hardness, which can better meet the production needs of various parts and objects, and extend the products they make. Service life. At the same time, compared with pure copper wire, when the nickel-plated copper wire is placed in the air, the stability of the whole wire body will be higher and the passivation ability will be stronger.

What is the purpose of adding a pull wire process when nickel plating on the surface of a copper wire?

1. Whether it is nickel plating on the surface of copper wire by electroplating or chemical method, the wire will be pulled during the whole nickel plating process, which can better improve the density of copper wire and coating parts. If the treatment in this aspect is not done, the color of the surface of the formed nickel-plated copper wire will be relatively dull and not smooth, which will affect the quality of the copper wire.

2. Increase production output and reduce production costs.

3. Increase the type of copper wire that can be produced. In the process of nickel plating treatment of copper wire, for some wire bodies with relatively small diameter requirements, a smaller diameter wire body can also be obtained by pulling wire treatment of the wire body, so as to better meet the practical needs of users. If the copper wire with a small diameter is directly plated with nickel, it is easy to break the wire body, which affects the production progress of the whole wire body.

Key words:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Related News