Copper wire surface coating is different, the role is also different

Release time:

2024-01-05

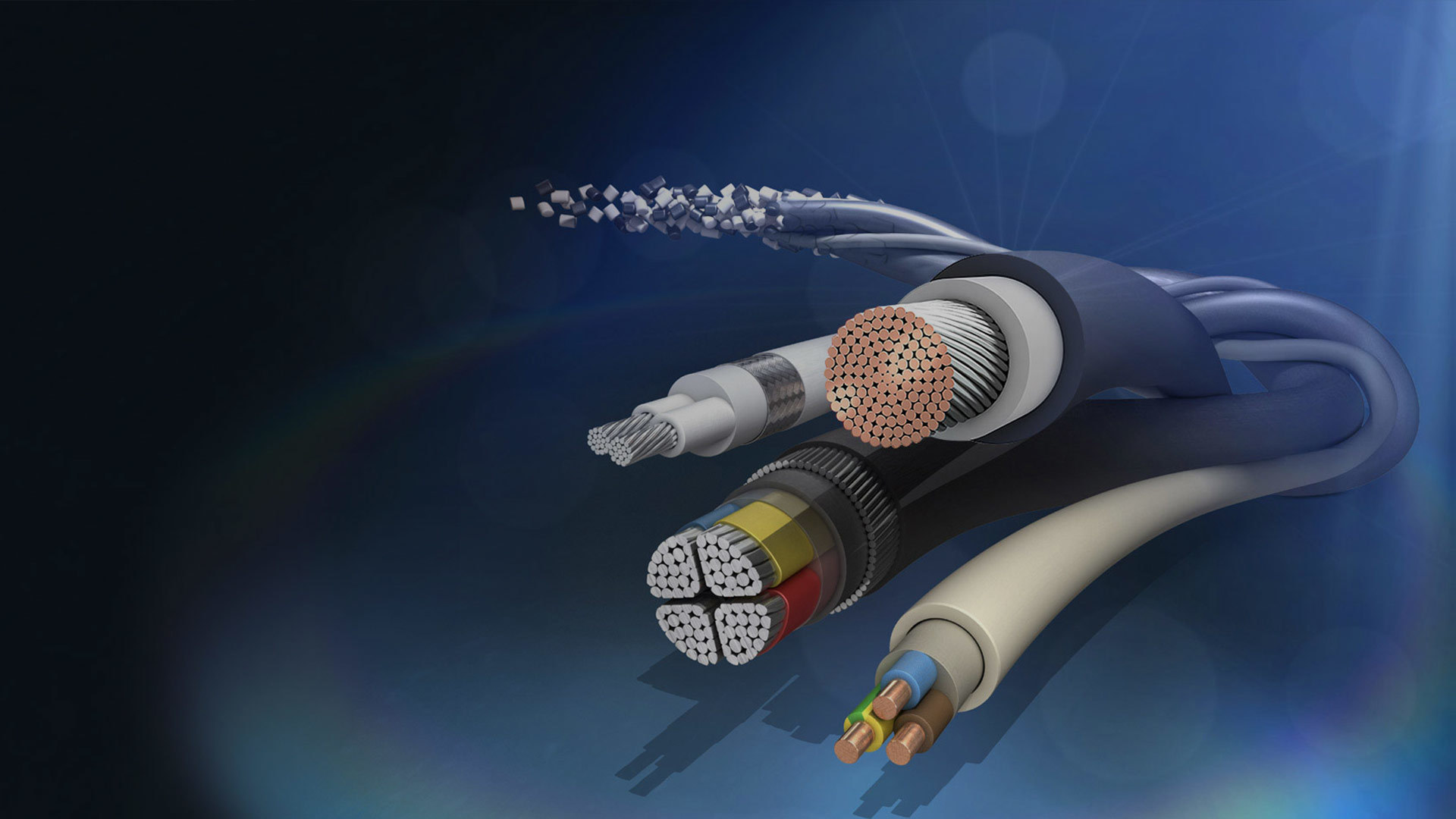

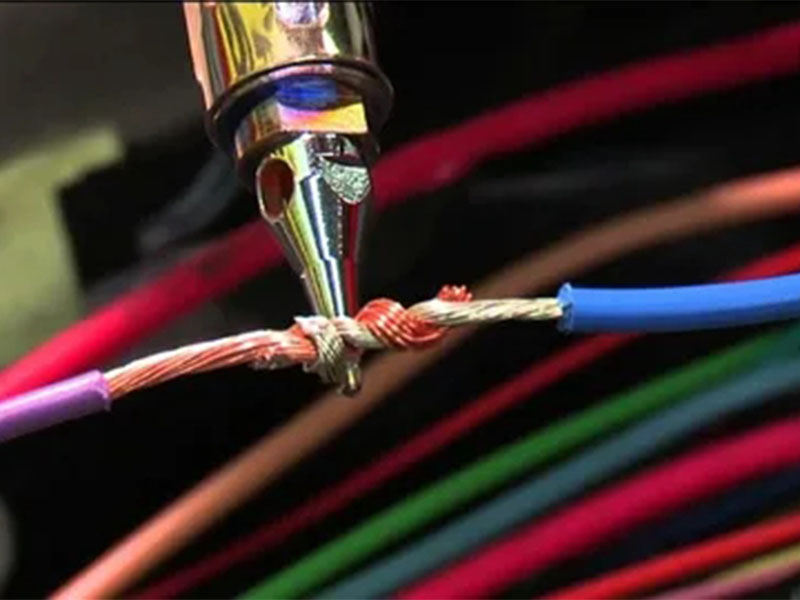

Copper wire is a very common type of metal in people's life and production, and it plays a different role in different industries. In the process of using copper wire in many industries, in order to improve its performance, different metals will be plated on its surface to meet the needs of practical applications. Let's take a look at the copper wire surface plated with different metals, what changes can happen.

Copper wire is a very common type of metal in people's life and production, and it plays a different role in different industries. In the process of using copper wire in many industries, in order to improve its performance, different metals will be plated on its surface to meet the needs of practical applications. Let's take a look at the copper wire surface plated with different metals, what changes can happen.

Nickel-plated copper wire

The so-called nickel-plated copper wire, that is, a layer of nickel metal is plated on the surface of the copper wire. After this kind of process, the temperature and conductivity of the whole metal will not change much, and the big difference is that when exposed to the air for a long time, the stability of the copper wire after nickel plating will be much stronger. At the same time, because the nickel metal itself has a strong passivation ability, so after the surface of the copper wire nickel plating, the hardness of the whole metal will increase, acid and alkali corrosion resistance, anti-wear performance, have a very good promotion, the entire copper wire can adapt to environmental changes will become stronger.

Silver-plated copper wire

This kind of copper wire, that is, a layer of silver is plated on the surface of the copper wire. After silver plating on the surface of the copper wire, it can effectively reduce the possibility of the copper wire being oxidized in the air to form a layer of molybdenum green. At the same time, the copper wire itself has poor conductivity. After the silver layer is plated on the surface, the possibility of oxidation reaction can be reduced and the heat dissipation performance of the whole copper wire can be improved. At the same time, it can also prevent the rubber in the insulation layer of the copper wire from sticking and becoming brittle, and improve the weldability of the entire copper wire.

Whether it is nickel-plated copper wire or silver-plated copper wire, compared to pure copper wire, whether it is the scope of use or durability, has been well improved, can bring more people's lives, production may. This is also an important reason why more and more copper wires on the market are plated with other metal-like materials.

Key words:

- All

- Product Management

- News

- Introduction

- Enterprise outlets

- FAQ

- Enterprise Video

- Enterprise Atlas

Related News